VACUDEST

Vacuum Evaporation System by H2OWe are the North American sales partner of vacuum evaporator VACUDEST, by H2O. VACUDEST integrates with Kontek technology to aid in wastewater recovery, discharge compliance or as a step to achieve ZLD.

The VACUDEST vacuum distillation system turns 100 percent industrial wastewater into up to 98 percent recyclable distillate and only 2 percent residue. The result is a substantial reduction in disposal costs and water consumption. VACUDEST is up to 90% more energy efficient than equivalent atmospheric evaporators.

Operating Costs approximately 10% of atmospheric evaporation systems.

An investment in VACUDEST wastewater treatment systms for industry usually pays for itself within the first two years.

Innovative technologies produce a crystal-clear distillate that is ideal for reuse in your own production.

Electric heat is used to raise the temperature of wastewater used in the initial fil l of the unit. The system recompresses steam produced with a vacuum pump to recapture the energy producing higher temperatures to heat the incoming wastewater.

No wastewater also means no pollution that can enter the environment and our waters. A good feeling for the protection of our world.

The VACUDEST is particularly compact. It provides efficient and safe industrial wastewater treatment in just one process step.

The system runs fully automatically.

VACUDEST plays a key role in achieving zero liquid discharge since a high percentage of water is reclaimed.

VACUDEST uses nature as its model: heat makes water vapor, rises and condenses into clouds. The falling rain is free of salt and pollution. Vacuum distillation uses this principle - only much more energy-efficient thanks to energy recycling.

VACUDEST Options Available

Activepowerclean grinding balls

Reduces scaling and blocking of pipes during the evaporation process. High flow rates inside the heat exchanger pipes circulate the grinding balls, reducing scaling. This add-on reduces operating costs by eliminating any additional chemical and manual cleaning of the heat exchanger pipes.

Destcontrol

Destcontrol regulation measures the pH value of the purified distillate. If the pH values change here, the neutralization agent is metered out directly into the VACUDEST evaporator to correct them, thereby settling any subsequent reactions.

Clearcat

Reduce COD and oil index of industrial wastewater in single process step, efficiently and reliably. The process uses physical and catalytic effects which requires no additional energy, auxiliary or operating materials. No additional operating costs required.

Purecat™

With the addition of the Purecat™ module, COD levels can now be reduced by up to an additional 50%. This means that the Purecat™ can be used for recirculation in almost all industrial sectors.

For More Information

Contact us for more information related to your specific application needs.

Other Evaporation Technologies

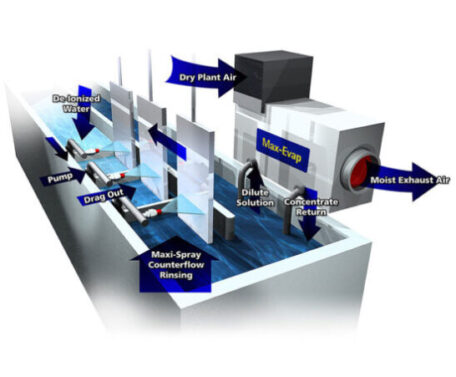

Atmospheric Evaporator

Reclaim drag-out, reduce wastewater production rate

Plating Rinse Optimization

for use with MAX-EVAP