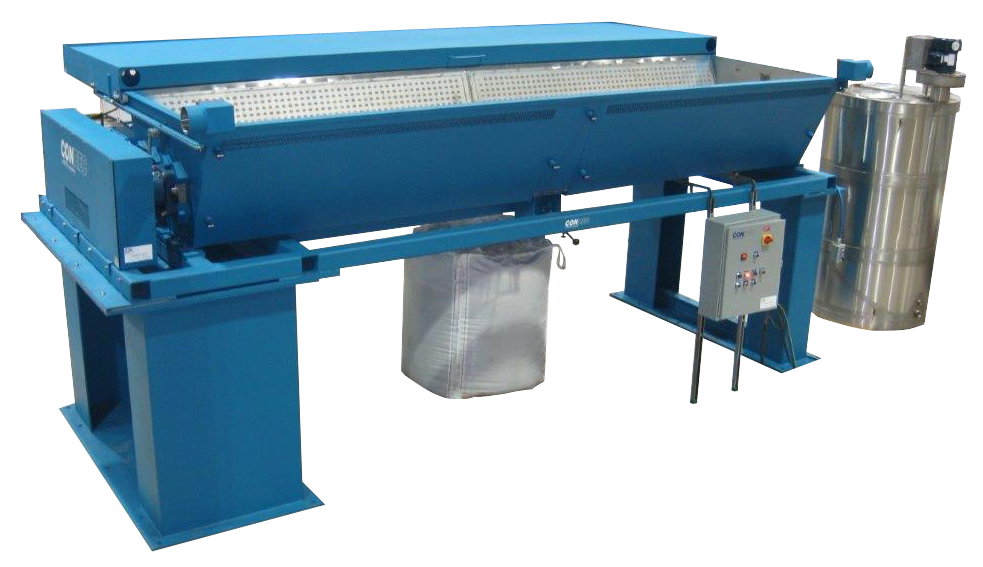

ConRec Sludge Dryers provide a full range of capacity, they are designed for small, medium, and high sludge volumes. We build each unit to fit under the Filter Press to eliminate hazardous sludge handling, this enables efficiently semi-continuous batch sequencing, reducing the volume and space of the sludge.

Even in small plating shops, sludge disposal costs can add up to big money. Now there is an affordable solution. The ConRec Sludge Dryer is now available from two to six cubic foot capacities, to meet the needs of shops and departments where large dryers are not necessary, or from eight to a hundred cubic foot to handle large sludge requirements.

In the small units, only 25″ and 26″ high, these Sludge Dryers fit directly under a 470 mm plate or 630 mm plate press, so it occupies no additional floor space. When used as a stand-alone dryer without a Filter Press, its footprint is not more than 4′ X 7.5′.

Space-saving is just the beginning, our Sludge Dryer can easily save you thousands of dollars each year. For example, four cubic feet of wet sludge may take up one cubic foot or less after drying.